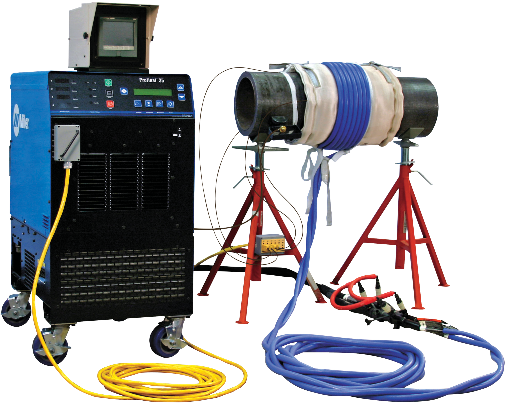

K & M Solutions is now offering the Miller Pro-Heat 35

Weld Pre-Heating and Stress Relieving

REDUCE PREHEATING TIME BY UP TO 400%

Miller’s Induction Heating system brings a part to temperature in a fraction of the time, compared to traditional flame and resistance heating processes. It also holds the part at the specified temperature.

With Miller’s Pro-Heat™, pre-heat time can be reduced by up to 400%. To put this in perspective, companies using the Pro-Heat™ have reduced pre-heating time from over two hours to just 30 minutes.

Miller Pro-Heat 35

Multiple Outputs

Provides two insulated connectors for air cooled blankets or liquid-cooled cables.

Low Consumable Costs

No fuel costs and minimal insulation costs. Insulation is reusable and may be used 50 times or more, reducing cost of disposal and replacement.

On-Board

Temperature Control

Provides for manual or temperature-based programming in a simple to learn operator interface.

Multiple Control

Thermocouple Inputs

Control on the hottest TC during heating and coolest TC during cooling for uniform heating and quality.

Open Output

Detection

Prevents system operation without a covered output receptacle (cable or protective plug).

Easy Set-Up

Achieved using preheat blankets or flexible heating cables combined with user-friendly insulation blankets. Easy to install primary power through panel that does not require removal of sheet metal.

APPLICATIONS

Transmission Pipeline – Construction/Repair

Pipe Fabrication Shops

Power Piping – Construction/Repair

Petrochemical – Construction/Repair

Shipbuilding

Mining Equipment

Maintenance

Drill Pipe Manufacturing

Shrink Fit

ISOLATION FAULT PROTECTION

Provides automatic system shut down should power source output short to ground. A sense lead provides direct feedback to the power source to sense fault condition.

LIQUID COOLED INDUCTION HEATING SYSTEM

Designed for preheating, hydrogen bake-out and stress relieving applications up to 788°C.

THE PRO-HEAT 35 ROLLING INDUCTION SYSTEM

A simple and cost effective heating solution which delivers fast and consistent heat to rotating parts up to 315 degrees.

UNIFORM HEATING

Heating is maintained along and through the heat zone by using induction to heat within the material. The surface of the part is not marred by localized conducted heat at higher than specified temperatures.

IMPROVED AND SAFER WORKING ENVIRONMENT

Welders are not exposed to open flame, explosive gases and hot elements associated with fuel gas heating and resistance heating.

CABLE IDENTIFICATION SYSTEM

Knows the type of cable attached and limits output to protect cables and blankets.

TIME-TO-TEMPERATURE

Faster than conventional processes due to the method of applying the heat, reducing heating cycle time.

AIR-COOLED INDUCTION HEATING SYSTEM

Designed for preheating applications up to 204°C.

SPECIFICATIONS

Input Power

400 – 460 V,

3 Phase,

50/60 Hz CE

Output Frequency

5 – 30 kHz

Rated Output

35 kW at 100% Duty Cycle

Input Amps at Rated Output

60 A, 400 V

kVA/kW at Rated Output

39/37

Dimensions (mm)

H: 669

W: 552

D: 933

Weight

103 kg

(Power Source Only)

If you would like to hire the Miller Pro-Heat 35 then please do not hesitate to contact us by sending us a message through our contact form or calling us on 0412 519 268